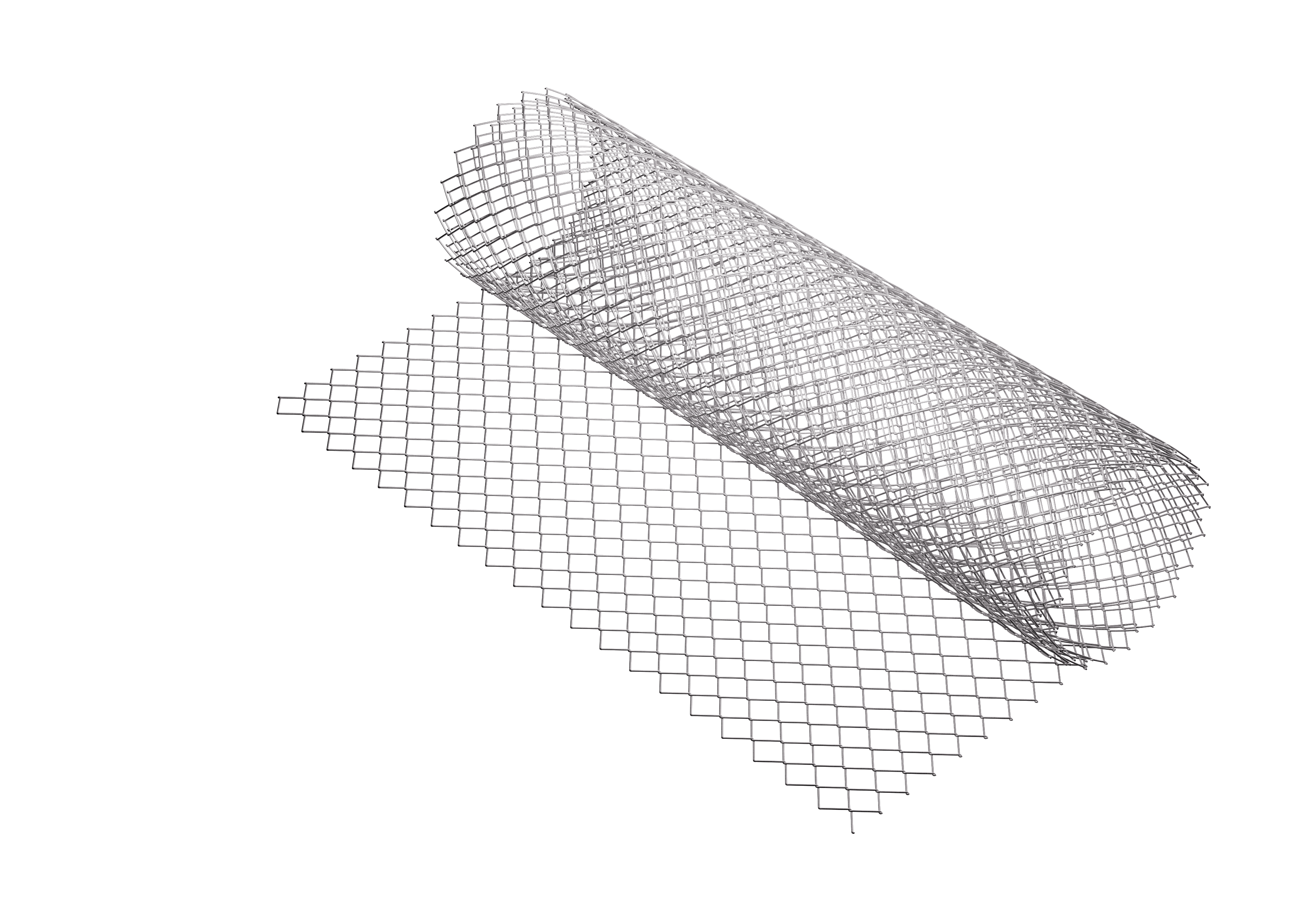

GALVANIZED WOVEN MESH

GALVANIZED WOVEN MESH

Galvanized woven mesh is a type of wire mesh made by weaving galvanized steel wire together to create a strong, durable, and versatile material. The process of galvanizing involves coating the steel wire with a layer of zinc, which acts as a protective barrier against corrosion. This layer of zinc significantly enhances the wire’s resistance to rust and other environmental factors, making galvanized woven mesh ideal for use in a variety of demanding applications, including underground mining, construction, and industrial settings.

The galvanizing process not only protects the wire from corrosion but also extends the life of the mesh, ensuring it remains reliable and functional even in harsh conditions. Galvanized woven mesh is known for its high tensile strength, making it capable of withstanding heavy loads and extreme environments. Additionally, the wire’s woven design provides flexibility, allowing it to be easily shaped or fitted to specific requirements.

One of the key benefits of galvanized woven mesh is its versatility. It can be used in various applications such as fencing, reinforcement in concrete, and as a protective barrier in mining and construction projects. The mesh helps stabilize the surrounding ground, providing additional support and safety in excavations or construction zones. Its durability and corrosion resistance make it an excellent choice for both temporary and permanent solutions.

ADJANTAJES OF ITS USE

Corrosion resistant

Greater adaptability to the rock mass

Easy handling and installation

Higher load resistance than standard woven meshes

FIELDS OF APPLICATIONS

Mining and support projects

Retaining pillars

Slope control

Rock mass retention

GALVANIZED WOVEN MESH TECHNICAL PROPERTIES